How to Enhance Manufacturing Flexibility with power & free conveyors

Is your production line experiencing bottlenecks? Rigid conveyor systems often cause congestion and struggle to handle varying processes or priorities. This inflexibility leads to inefficient workflows and limits your ability to customize products.

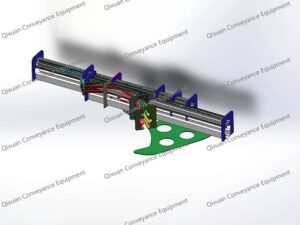

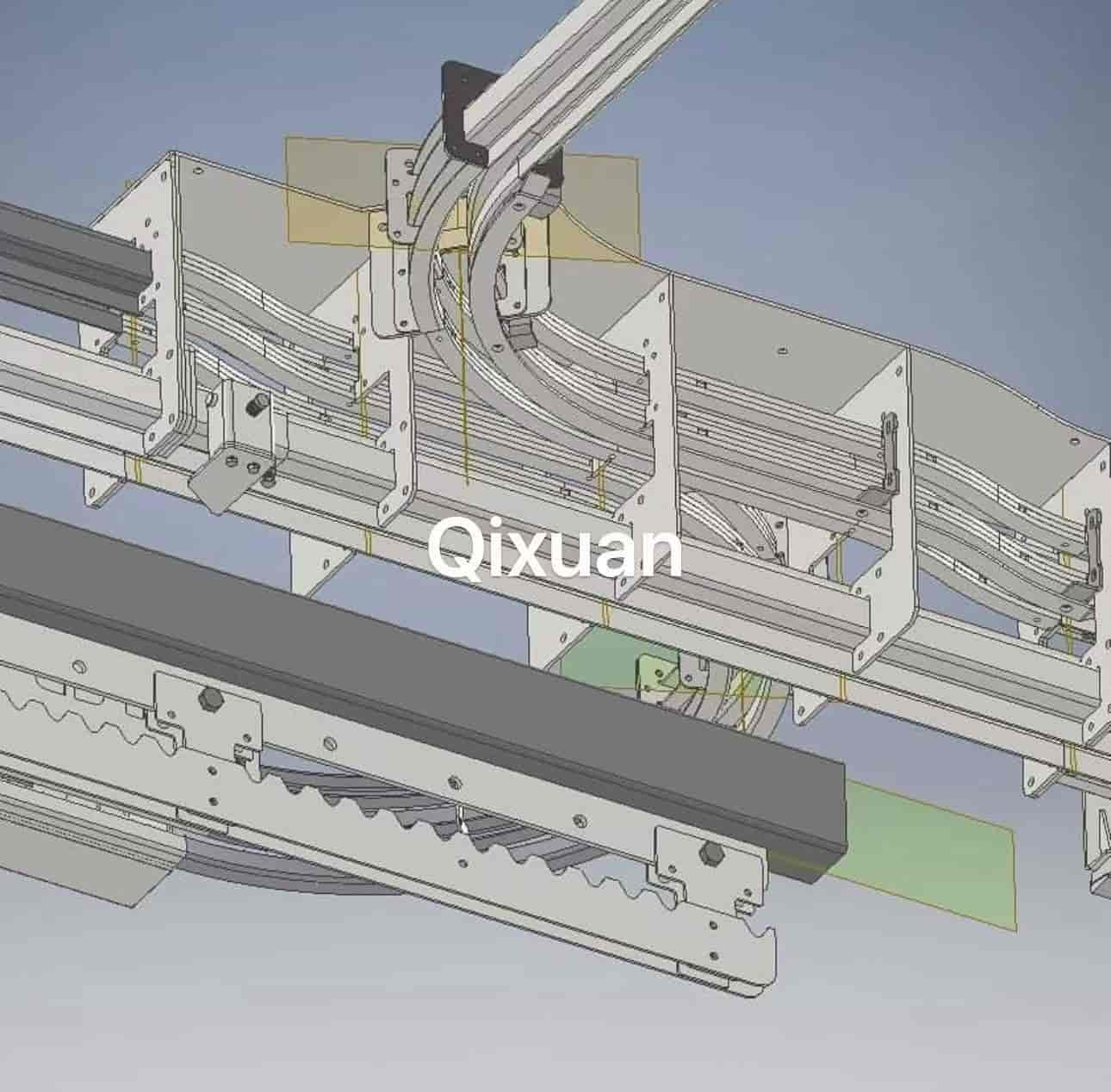

Accumulation conveying systems represent the ultimate solution for intelligent material handling. By separating the drive unit from freely moving carriers, it allows individual loads to stop, accumulate, and change paths independently without halting the entire line. This delivers unparalleled flexibility for complex manufacturing, painting, and assembly operations. You can effortlessly create buffers, prioritize orders, and integrate diverse workstations.

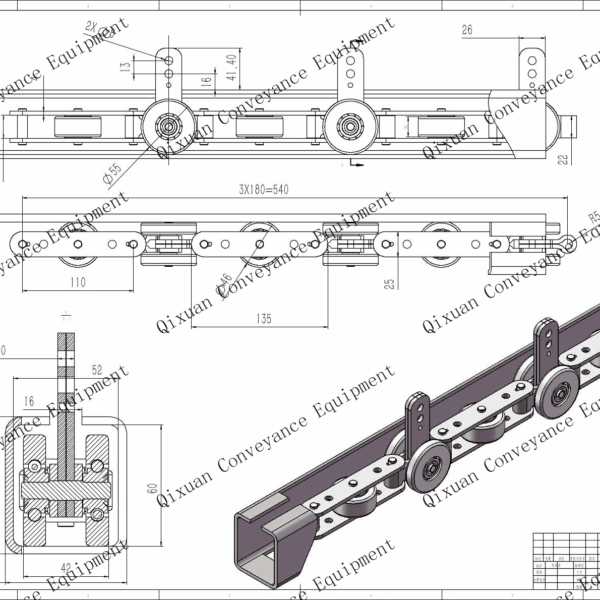

Key Technical Specifications for Informed Decision-Making:

Load Capacity: Systems are engineered to handle loads from 75 kg to 2000+ kg per carrier, accommodating everything from small components to heavy automotive frames.

Accumulation Capability: Zero-pressure accumulation is a core feature, preventing product damage and enabling workflow partitioning.

Path Switching: Automatic switching facilitates complex routing, supporting instant sorting and seamless merging operations.

Control System: Modern power and free conveyor systems utilize Programmable Logic Controllers (PLC) for precise tracking and control of each carrier.

Customer Success Story: Automotive Assembly Optimization

A major German automotive plant faced challenges in its paint process. Varied drying times required for different vehicle models created bottlenecks. By implementing our accumulation conveyor system, they achieved dynamic zoning and accumulation. Now, conveyors can pause independently to ensure perfect drying, boosting production line throughput by 25%.

Frequently Asked Questions (FAQ)

Q: Where are Power and Free conveyors typically used?

A: They excel in complex applications like automotive paint shops, assembly lines, storage and retrieval systems, and any process requiring routing flexibility.

Q: Why choose a Power and Free system over traditional conveyor belts?

A: The key advantage lies in independent carrier movement. This enables accumulation, variable speed control, and automated sorting—capabilities unavailable in continuous flow systems.

Q: How does the system handle maintenance?

A: Zone control allows one section of the line to stop for maintenance while the rest continues operating, minimizing overall downtime.

Q: Can these systems integrate into existing production lines?

A: Yes. We specialize in designing customized Power and Free solutions that connect seamlessly with your existing equipment for a smooth upgrade.

Ready to eliminate bottlenecks and bring unmatched flexibility to your operations? Our meticulously engineered Power and Free conveying systems are designed to maximize your productivity and adaptability. Contact our experts today for a free consultation and a system design tailored to your specific needs. Request a free quote to discover how we can transform your material handling workflow.

No comment