Seamless Replacement Chains for Your CALDAN Conveyor System

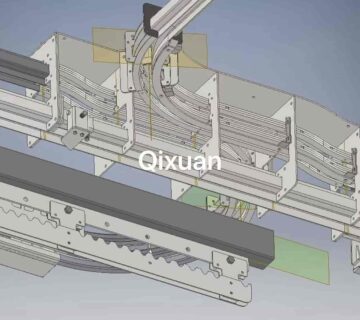

For facilities operating CALDAN overhead conveyor systems, maintaining peak efficiency hinges on the reliability of its core component: the conveyor chain. Sourcing genuine OEM replacement parts can involve long lead times and significant cost. We offer a professional, cost-effective alternative: high-precision, fully compatible replacement chains engineered specifically for CALDAN conveyor models.

Our chains are not mere substitutes; they are manufactured to the exact specifications, dimensions, and performance standards required for seamless integration into your existing CALDAN system, ensuring uninterrupted operation and optimal performance.

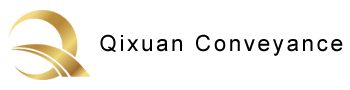

Understanding Your CALDAN Conveyor Chain

CALDAN systems typically utilize robust, precision-engineered chains featuring the following characteristics:

High Tensile Strength: For handling significant loads in automotive, paint shop, or assembly line applications.

Rivetless Design: Allows for easy link assembly, disassembly, and maintenance without specialized tools.

Precision Engineering: Ensures smooth engagement with sprockets and smooth travel along the track, minimizing wear and vibration.

Our replacement chains are meticulously crafted to replicate these critical characteristics.

Our Replacement Chain Solution: Key Features & Benefits

100% Dimensional & Mechanical Compatibility

We produce chains that match the exact pitch, inner width, pin diameter, and link plate geometry of your original CALDAN chain.

This guarantees perfect fit with existing sprockets, trolleys, and track systems, eliminating modification costs and downtime.

Superior Material & Manufacturing Standards

Constructed from high-grade alloy steel (e.g., C45, 42CrMo), forged and heat-treated to achieve optimal hardness, tensile strength, and wear resistance.

Advanced heat treatment processes (quenching and tempering) ensure core toughness and surface durability, extending service life.

Rigorous Quality Assurance

Every production batch undergoes stringent testing, including hardness testing, dimensional inspection, and load testing.

Our quality protocols align with international standards such as ISO 4347 and DIN 8165, ensuring consistent, reliable performance.

Significant Cost & Lead Time Advantages

By specializing in replacement chains, we streamline production and offer highly competitive pricing without compromising quality.

We maintain strategic stock levels and offer flexible production schedules, dramatically reducing delivery times compared to standard OEM channels.

Expert Technical Support

Our engineering team can assist with chain selection, wear analysis, and troubleshooting. We provide detailed technical datasheets and installation guidance.

Technical Specifications at a Glance

Feature Our Specification Benefit for Your CALDAN System

Chain Type Drop-Forged Rivetless Chain (or as per model) Direct OEM replacement.

Materials Alloy Steel, Heat-Treated High strength, abrasion resistance, and longevity.

Compatibility Designed for CALDAN C-series / Specific Models Guaranteed fit and function.

Process Precision Forging, CNC Machining, Heat Treatment Consistent quality and mechanical properties.

Surface Black Oxide / Phosphate Coating / Galvanized Corrosion protection tailored to your environment.

Standards Meets or exceeds relevant ISO/DIN standards Assured performance and reliability.

Common Applications for Our Replacement Chains

Automotive Paint Shops: Replacing chains in CALDAN systems used in pre-treatment, painting, and curing ovens.

Final Assembly Lines: Maintaining smooth transport of vehicle bodies or large assemblies.

Industrial Finishing Lines: For systems handling appliances, furniture, or metal products.

General Overhead Conveyance: Any CALDAN system in logistics, manufacturing, or distribution.

FAQ: Replacing Your CALDAN Conveyor Chain

Q1: Are your chains truly compatible with my specific CALDAN model?

A1: Absolutely. We require your existing chain sample or precise model number/specifications. We then manufacture to match, ensuring 100% compatibility. We provide samples for verification before full order production.

Q2: How does the wear resistance compare to the original chain?

A2: Our chains utilize similar or superior grade materials and controlled heat treatment. The result is a chain with comparable, and often improved, wear characteristics, validated by hardness and metallographic testing.

Q3: Can you supply a complete chain assembly with attached trolleys?

A3: Our core expertise is in manufacturing the chain itself. We can supply the complete chain in preset lengths or as individual links. For trolleys or complete assemblies, we recommend using your existing compatible trolleys or sourcing them separately.

Q4: What is your typical lead time?

A4: For standard CALDAN chain types, we often have stock or can produce within 3-4 weeks. Lead times vary based on specification and quantity. Contact us for an exact schedule.

Why Choose Us as Your Chain Partner?

We are a specialized manufacturer focused on high-quality conveyor chains. By choosing us, you are not just buying a part; you are gaining a reliable, responsive partner dedicated to keeping your production line running.

OEM-Level Quality, Competitive Price

Guaranteed Compatibility & Performance

Faster, More Flexible Supply

Direct Engineering Support

Ready to Optimize Your Conveyor Maintenance?

Don’t let chain replacement be a bottleneck. Request a quote or consult with our technical team today.

Contact us now with your CALDAN chain details or specifications. We’ll provide a competitive proposal, technical data, and a clear path to seamless replacement.

No comment