Is your overhead conveyor system causing you headaches? Are you constantly battling with chain derailments, excessive maintenance, and cleanliness issues in your facility? These problems lead to costly downtime, product damage, and increased labor costs. For manufacturing managers in Europe and America, finding a robust solution is critical for maintaining efficient and profitable operations.

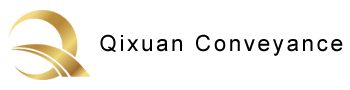

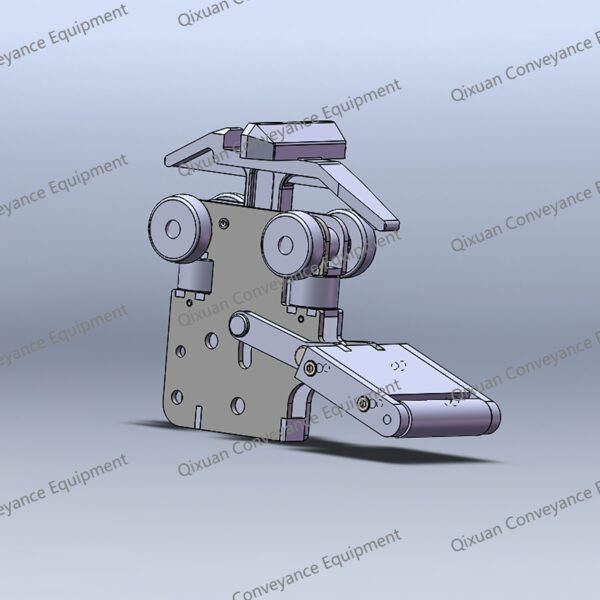

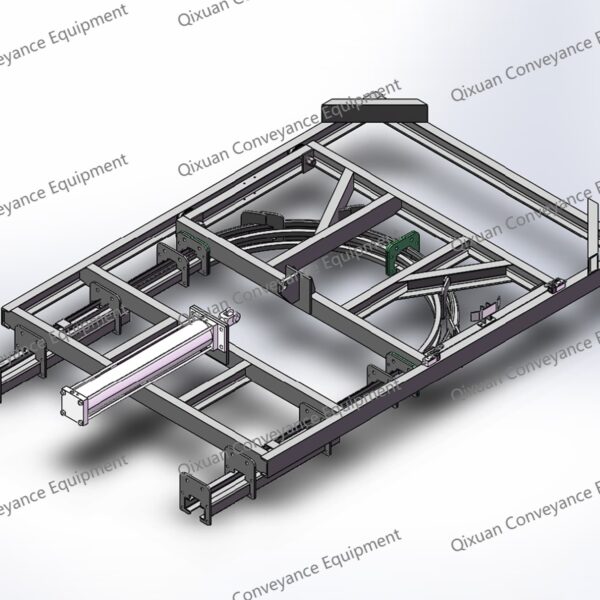

he enclosed track conveyor chain is the engineered solution to these common pain points. Its unique enclosed track design completely encapsulates the roller and chain, preventing dust, debris, and moisture from interfering with operation. This sealed structure ensures superior reliability and protects your product and production environment from contamination. Built from high-tensile strength alloy steel and often featuring a durable powder-coated finish, these chains are designed for long-term, heavy-duty use.

Key Technical Advantages:

Load Capacity: Designed for medium to heavy-duty applications, with standard capacities ranging from 50kg to over 500kg per carrier.

Low Maintenance: The enclosed design significantly reduces wear and tear by keeping lubricant in and contaminants out, requiring less frequent servicing.

Clean Operation: Ideal for environments where hygiene is paramount, such as food processing or pharmaceutical manufacturing, as it prevents grease and debris from falling onto products below.

Smooth and Quiet:The precision-engineered track ensures smooth movement and operates more quietly than open-style chains, improving the workplace environment.